-

Notifications

You must be signed in to change notification settings - Fork 8

Soldering tiny SMD with wick

I was always afraid to solder anything with smaller grid than 0.1" (2.54mm) - especially when my vision is not best...

However by chance I found really interesting tip on: https://www.sparkfun.com/tutorials/96

It is that simple:

- Put as much solder as you can to pins - ignoring any bridges

- Remove excessive solder and bridges with wick.

And that's All!

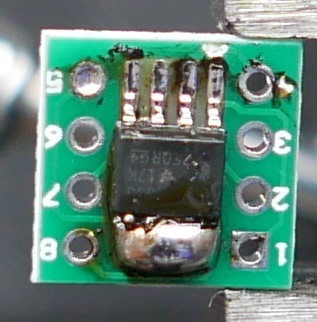

Here is an example - NE555 in SO8 package 0.05" (1.27mm) on SO8 and SSO8 breakout board Top 4 pins were already fixed with solder wick. Bottom 4 pins are before "treatment":

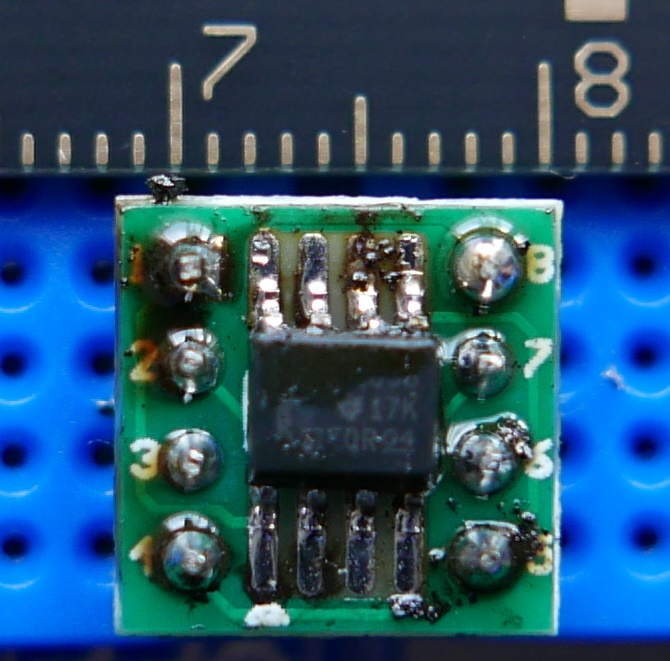

And here is final result - both SO8 package rows were cleaned with wick. Additionally standard 0.1" 4x pinhead connectors were soldered (no wick needed).

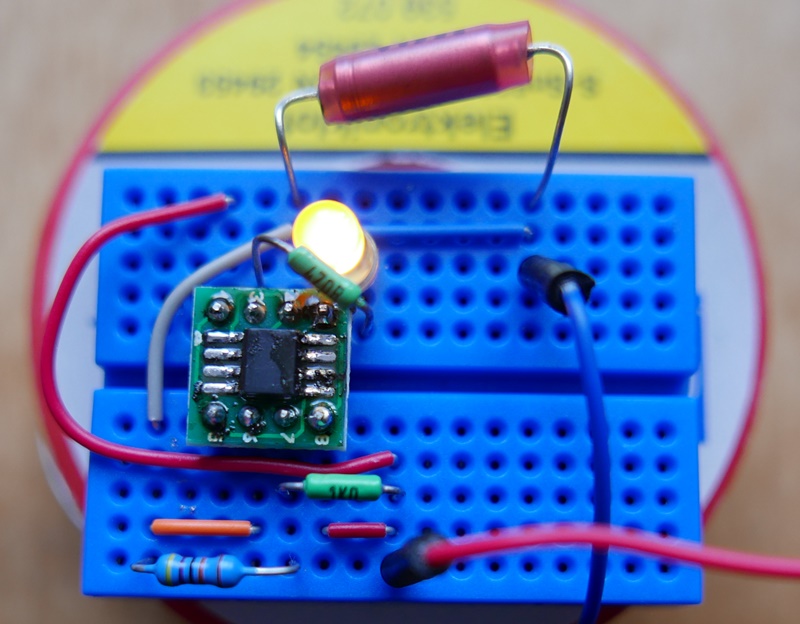

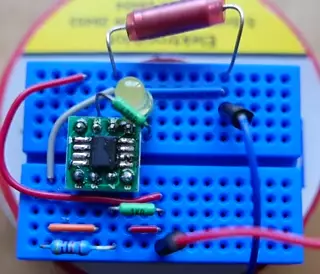

And here is moment of truth - NE555 blinker:

- from https://how2electronics.com/led-blinking-circuit-using-555-timer/ Using standard bread-board:

And possibly animation:

That tip from https://www.sparkfun.com/tutorials/96 was game changer for me - finally able to use at least some SMD parts when PDIP packages are harder and harder to get.

Also thank to https://how2electronics.com/led-blinking-circuit-using-555-timer/ (classic NE555 blinker) I was able to verify that NE555 really survived my soldering and is working properly.

Copyright © Henryk Paluch. All rights reserved.