-

Notifications

You must be signed in to change notification settings - Fork 20

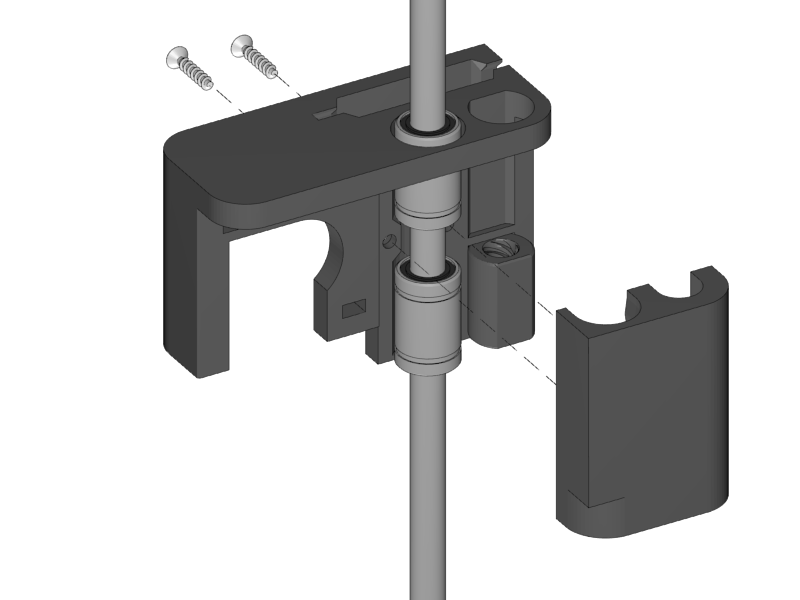

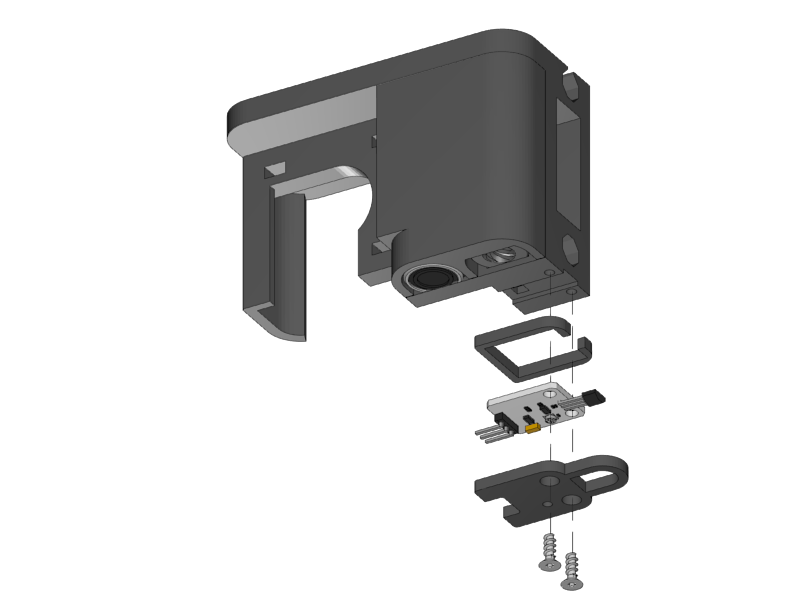

Section 3.1 Assembly of the XZ Unit Mounting the X Axis

|

|

|

|

|

|

|

|

|

|

|

-

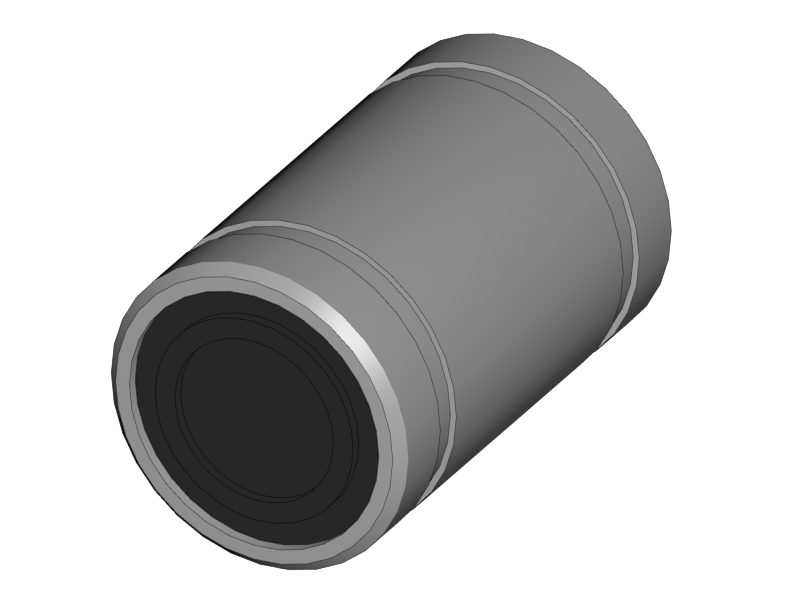

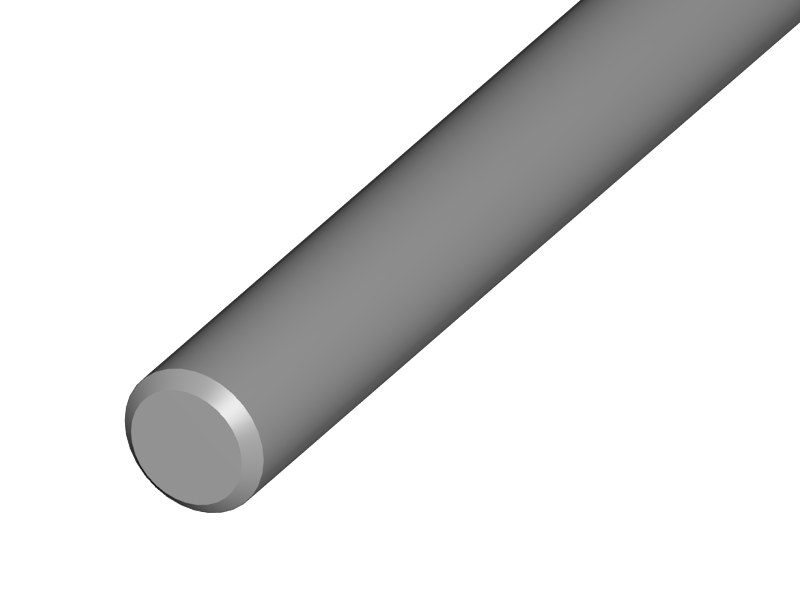

Put the linear bearings onto any of the smooth rods

-

This is to keep the bearings straight while you mount them.

-

-

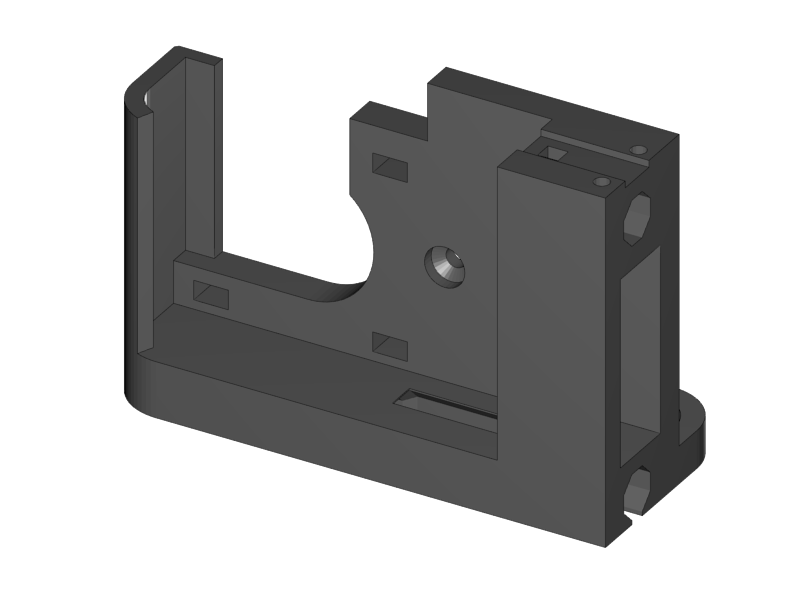

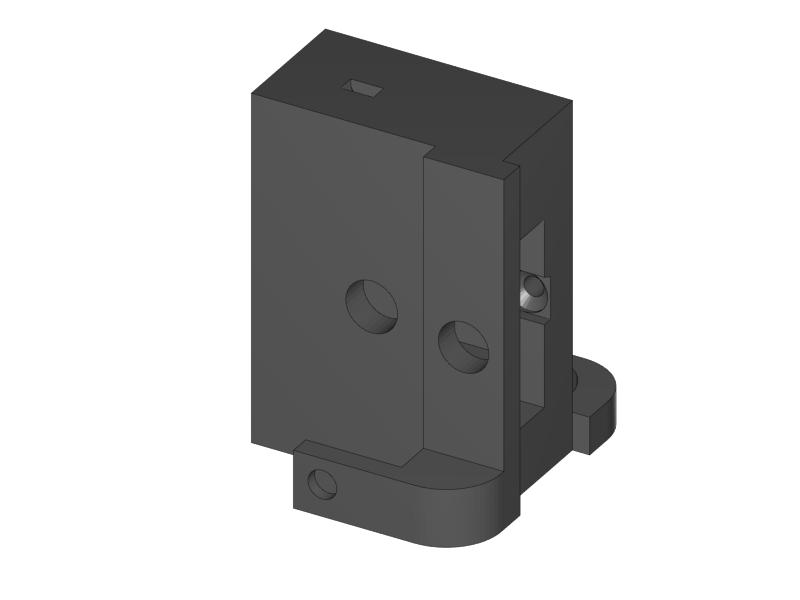

Put the bearings and the rod into the bearing slots of the X-Motor

-

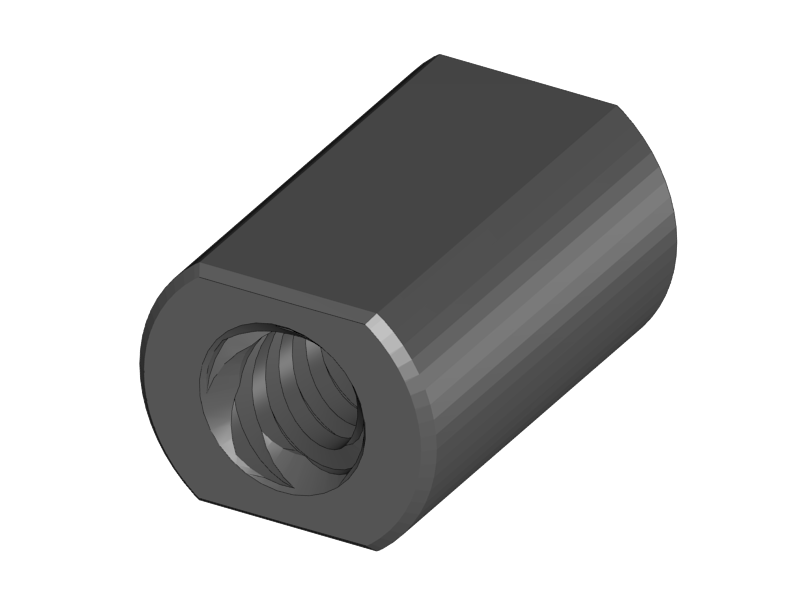

Put the ACME Nut into the slot of the X-Motor Holder

-

You can find the ACME Nut on the threaded rod of your linear stepper motor

-

-

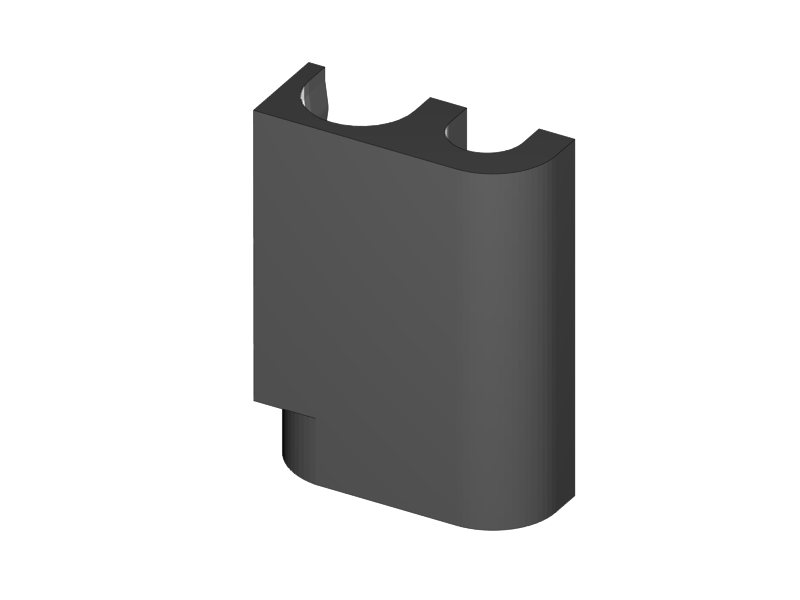

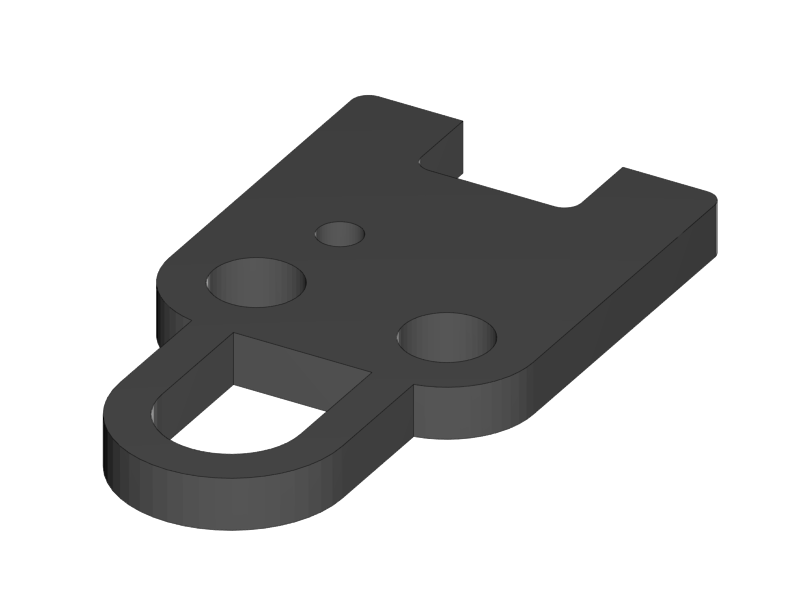

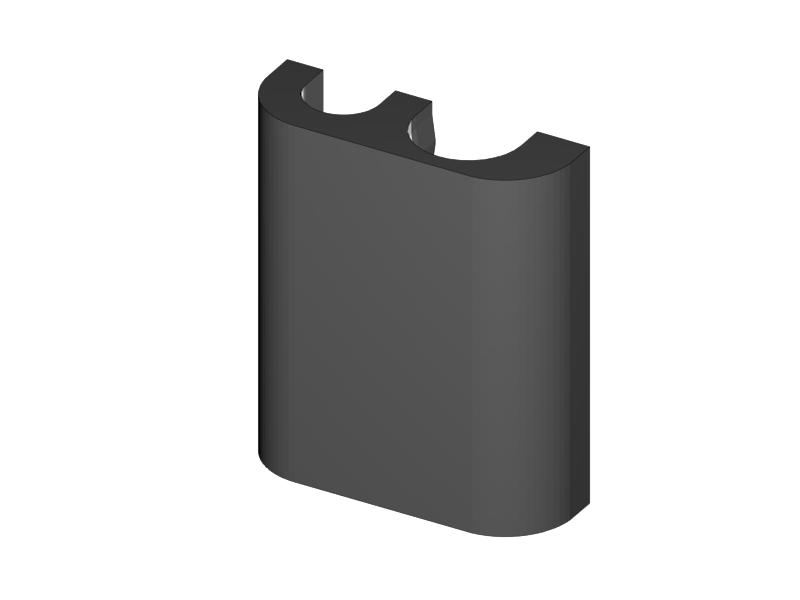

Place the Bearing Holder

-

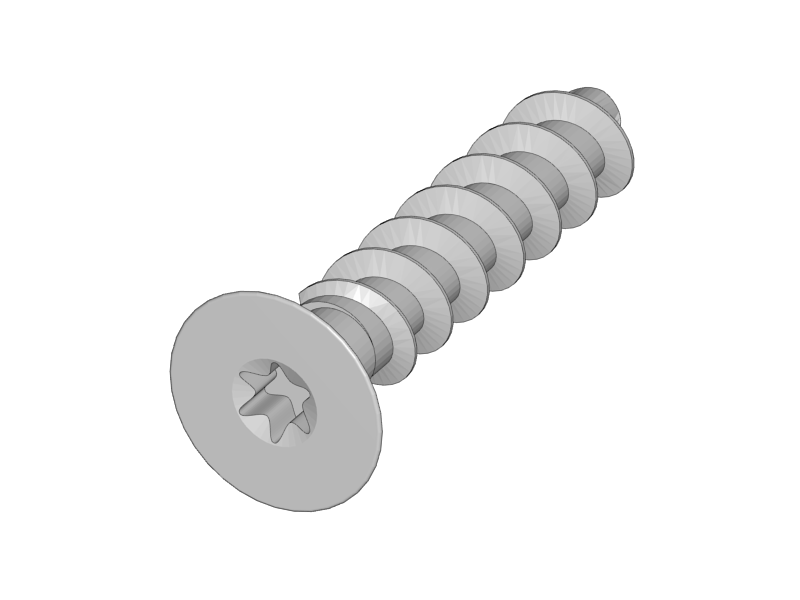

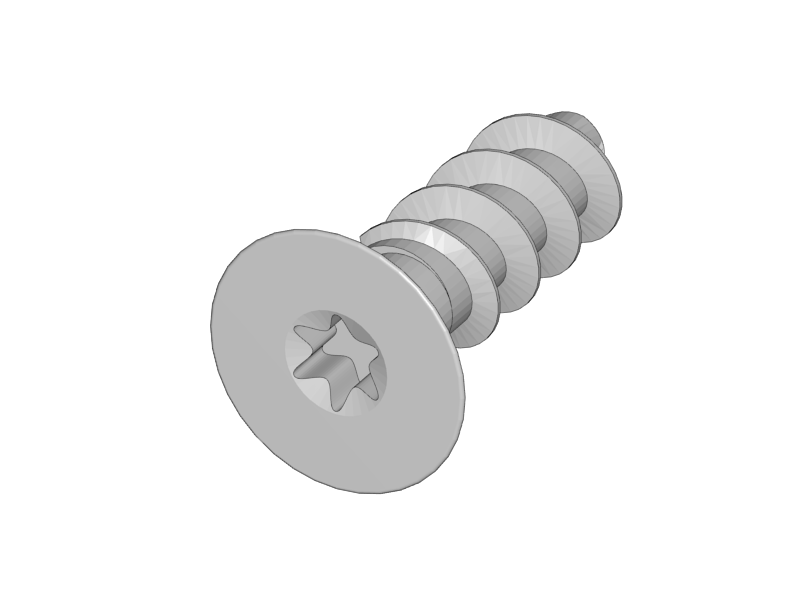

Fix the Bearing Holder with the two Torx screws.

-

Remove the smooth rod

|

|

|

|

|

|

|

-

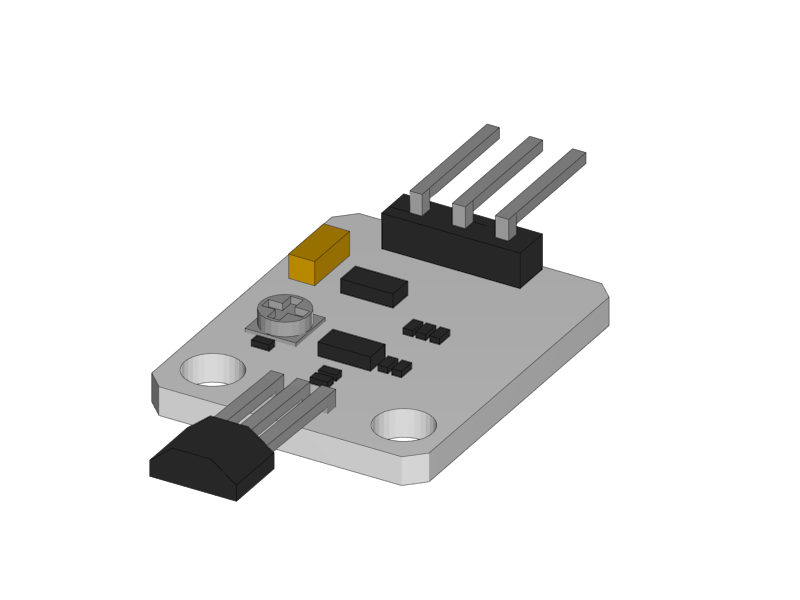

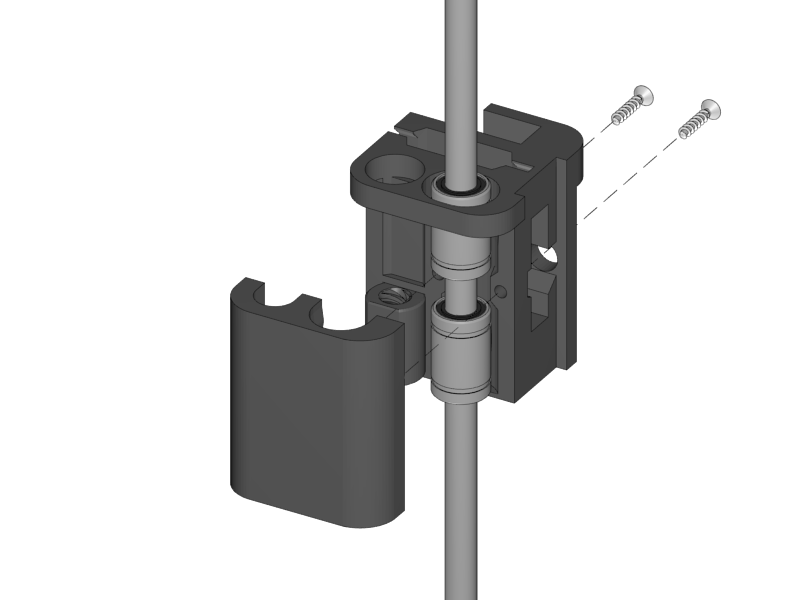

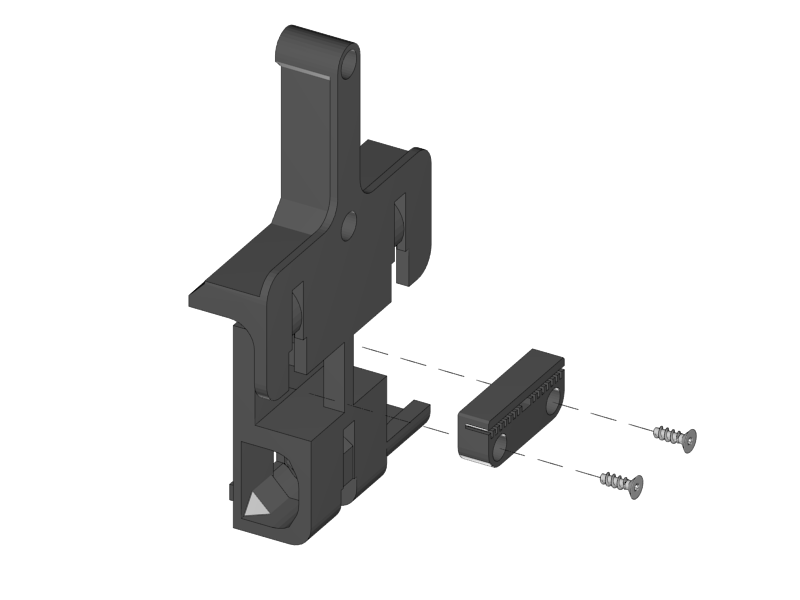

Mount the endstop with its cover onto the X-Motor assembly.

-

Don’t make the screws too tight.

|

|

|

-

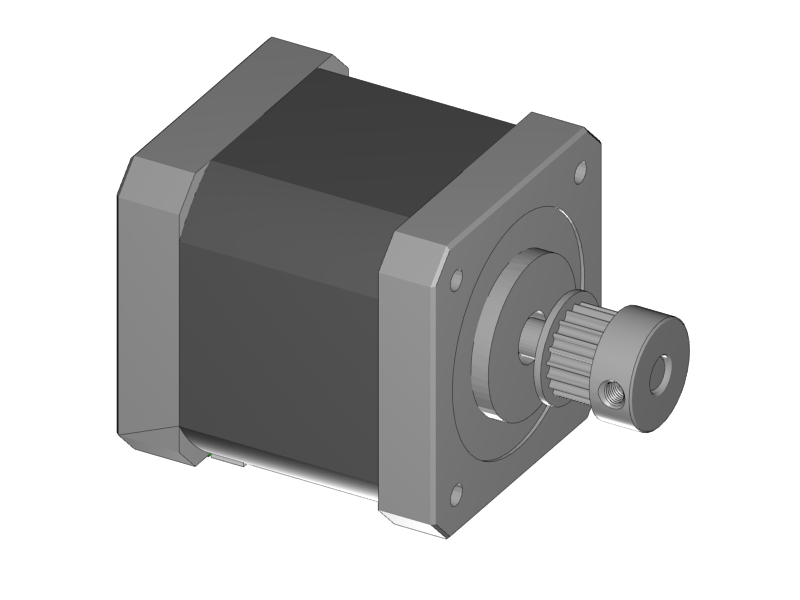

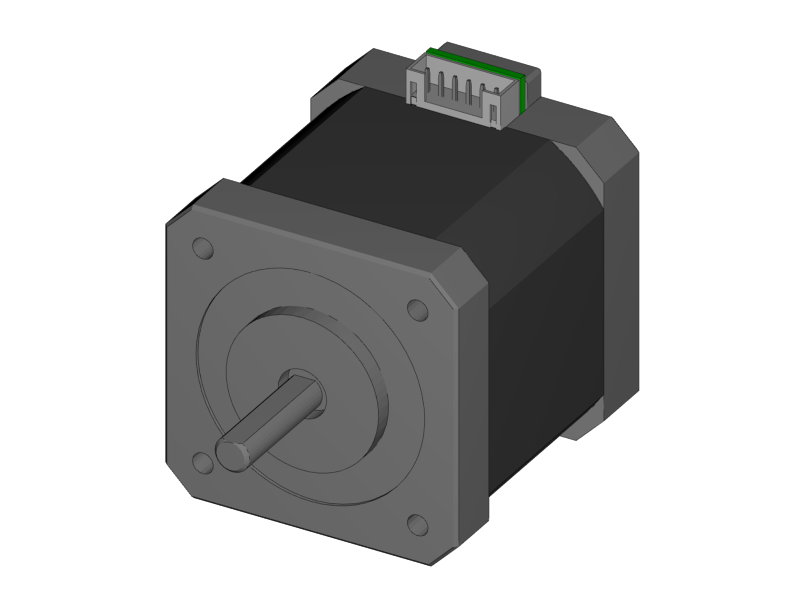

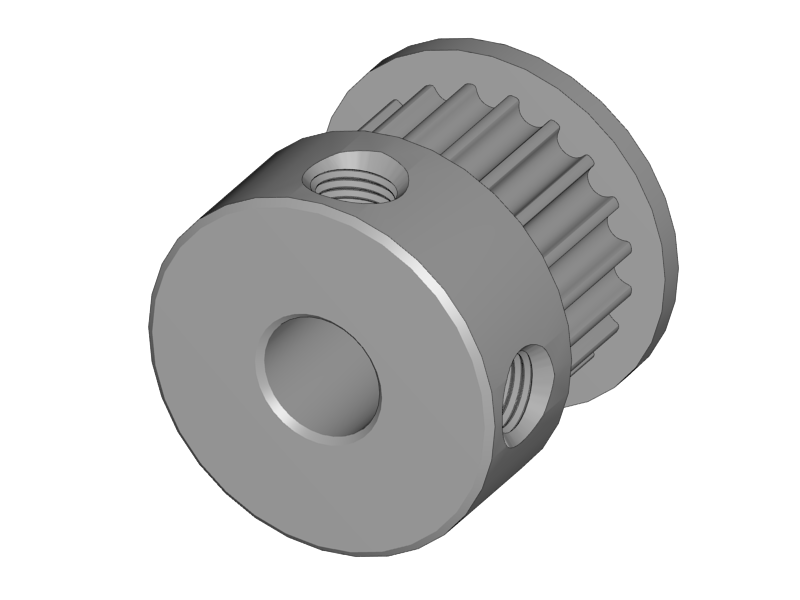

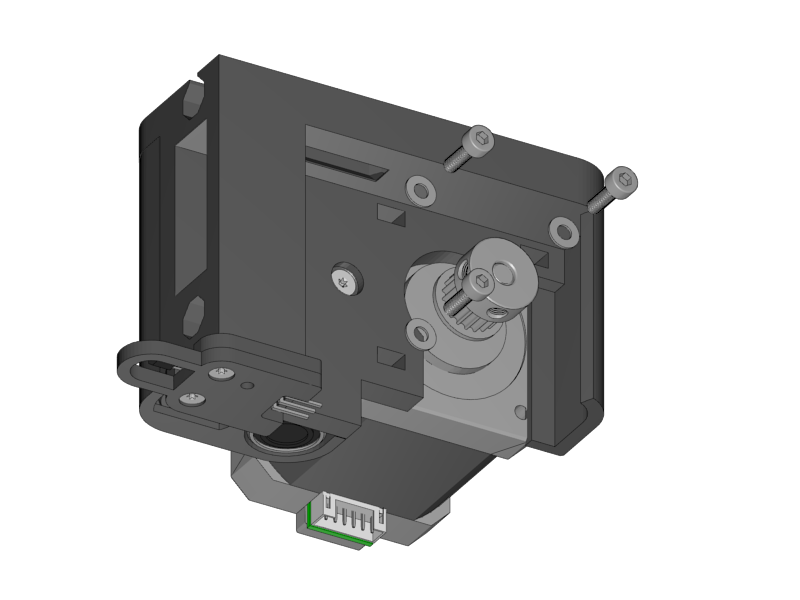

Mount the pulley onto the motor shaft.

-

Fix it with the two little set screws that you can find in the white bag in your RUMBA electronics box.

-

The distance between the motor and the pulley is 4.5mm.

|

|

|

-

Mount the motor onto the X-Motor holder.

|

|

|

|

|

|

|

|

|

|

|

-

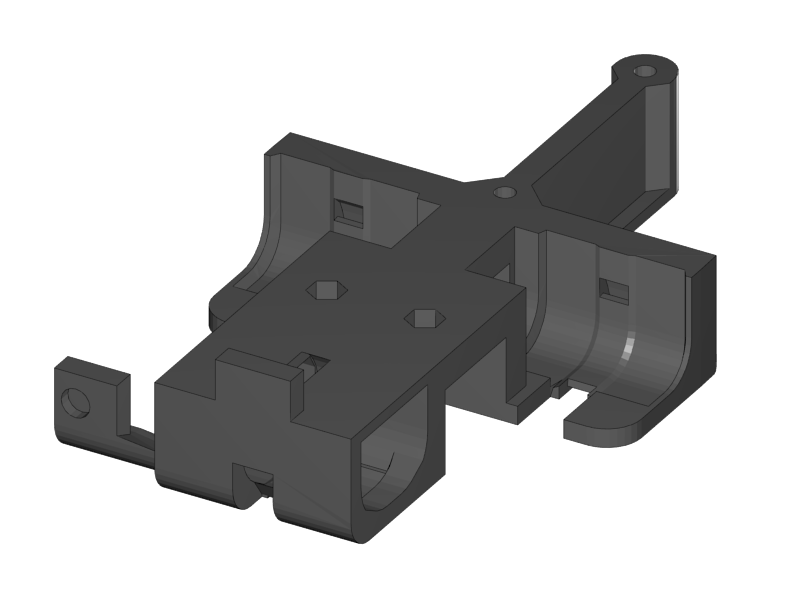

Put the linear bearings onto a smooth rod

-

Put the linear bearings with the smooth rod into the pocket for the bearings

-

Put the ACME Nut in position

-

Place the bearing holder

-

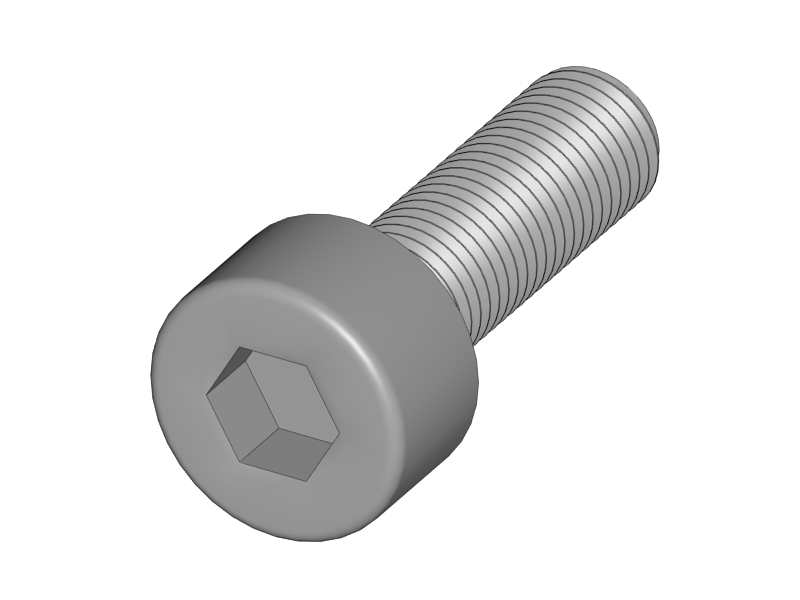

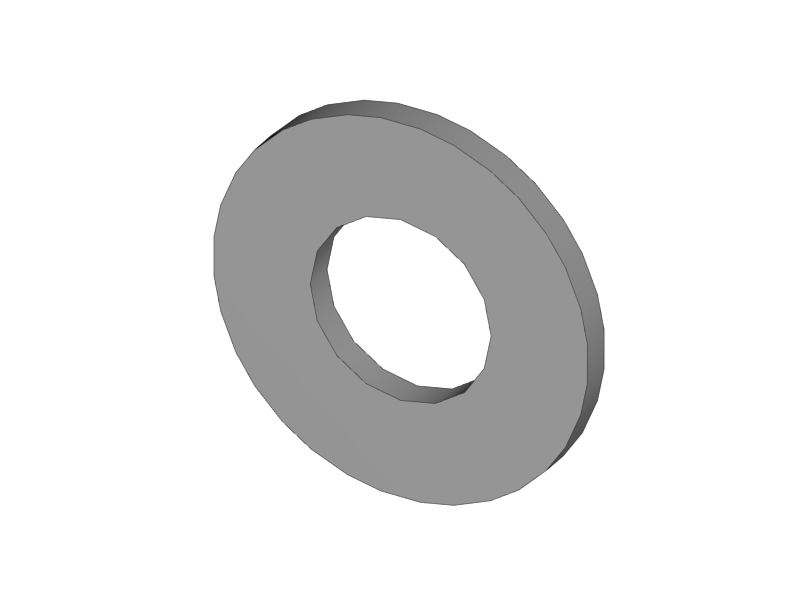

Fix it with two M3x16 Torx screws

-

Remove the rod

-

Note: the bearings can move left and right a couple of millimeters (with some friction). This is to avoid load on the bearings that can be caused by tolerances in the length of the linear rods of the X-Axis.

|

|

|

|

|

-

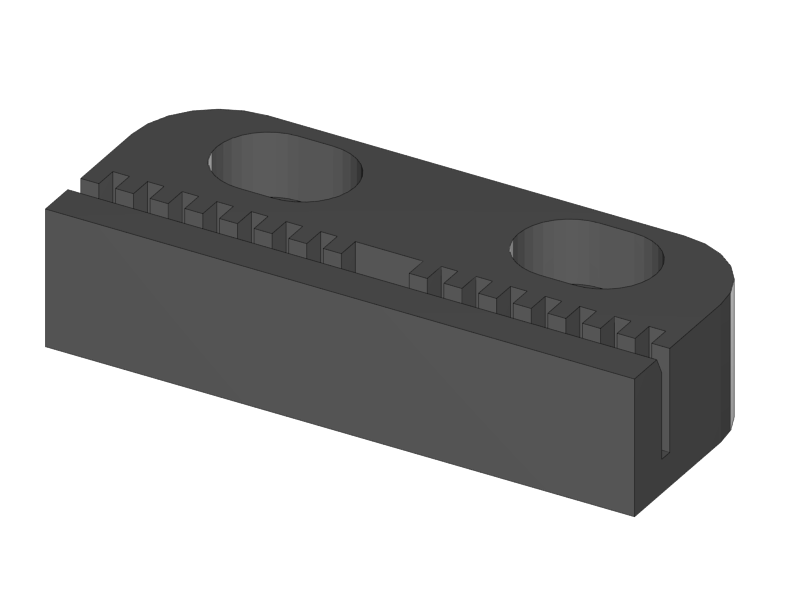

Pierce the holes in the X-Carriage.

-

The hole is closed of with one print layer for good print results. You can easily pierce it by pushing with a small allen key or screw driver from the other side.

-

-

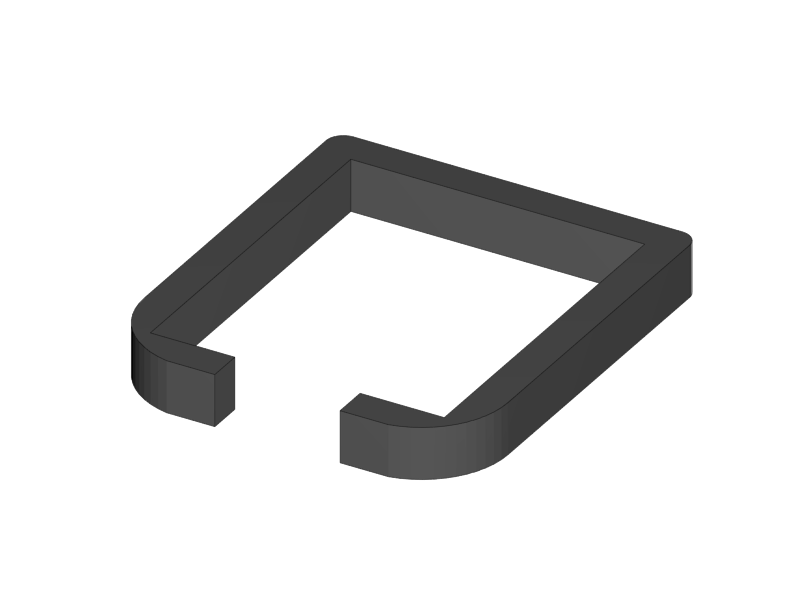

Slide the X-Teeth into position

-

Fix the teeth with the screws.

|

|

|

|

|

-

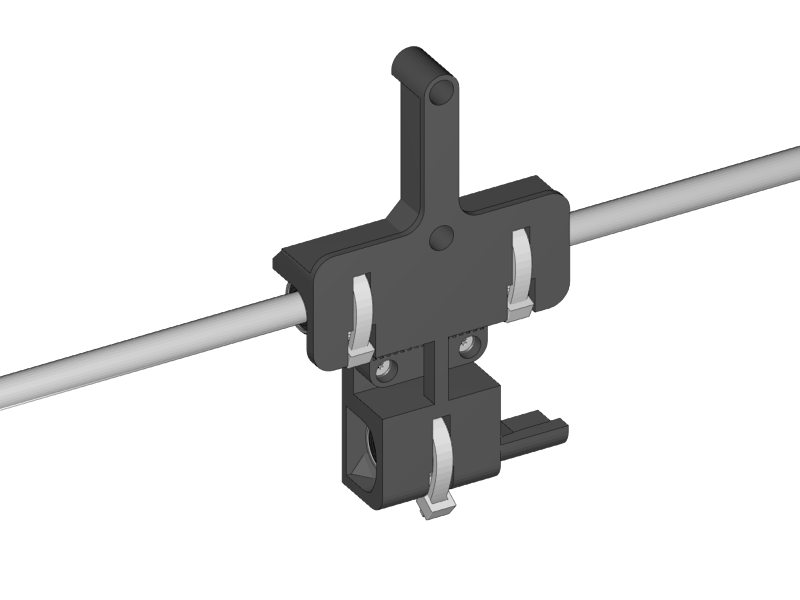

Place the upper two bearings into their slots

-

Slide a smooth rod through the bearings

-

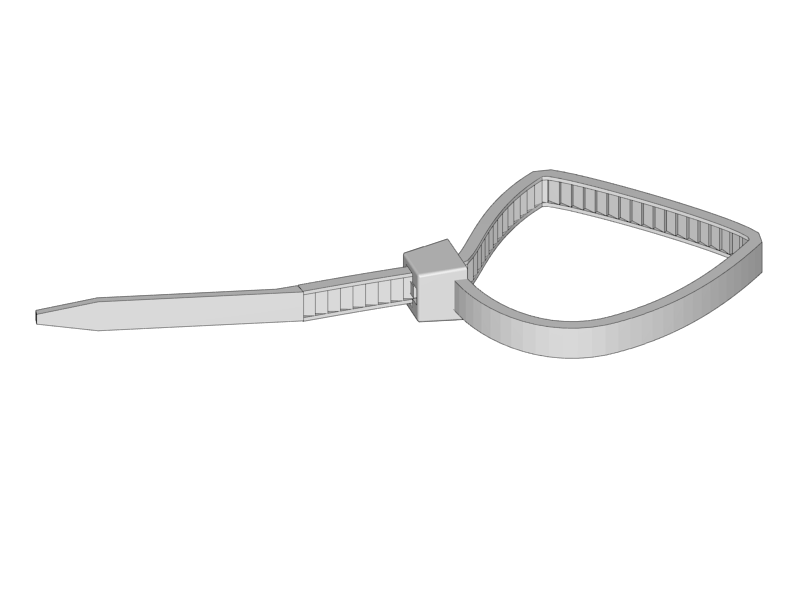

Mount the upper two bearings with a ziptie. Mind the orientation of the head.

-

If you don’t have a big ziptie, fix it with TWO small zipties for better stability.

-

-

Remove the smooth rod

-

Push in the lower linear bearing

-

Mount it with a ziptie.

|

|

|

-

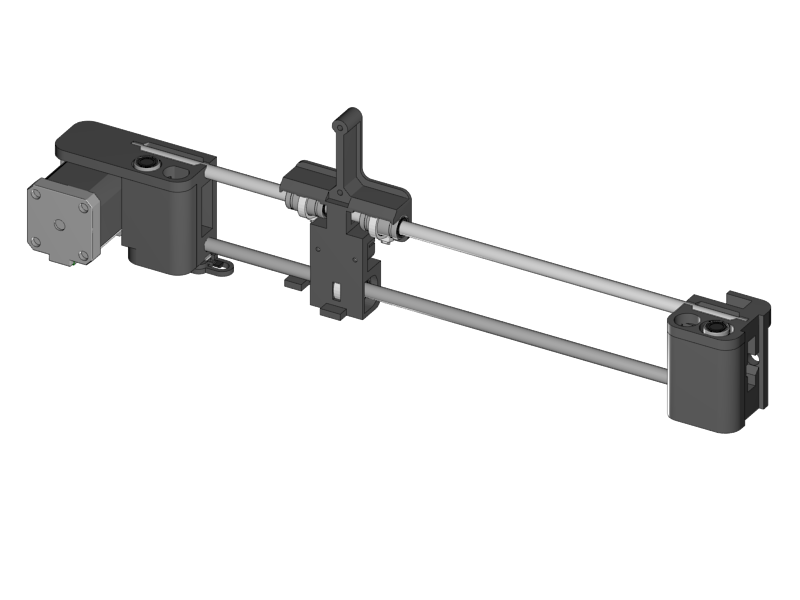

Slide the long (400mm) smooth rod into the upper hole of the X-Motor holder

-

Make sure it reaches to the end.

-

If it goes too stiff you can put the end into a hand drill. Do not use a hammer.

-

-

Slide the short smooth rod in the the X-Motor holder

-

Slide the X-Carriage assembly onto the rods. Mind the orientation!

-

Slide the X-Idler onto the smooth rods. Again make sure that they reach until the end of the hole.

-

If it goes stiff make a light twisting movement with you hands while you push the plastic parts more and more together.

-

##i3 Berlin

1 Introduction

1.1: History

1.2: Tools and Parts

1.3: Preparing the Casings

2 Assembly of the Y-Unit

2.1: Rods and Power Supply

2.2: Front- and Back- Plate

2.3: Mounting Y-Carriage and Belt

3 Assembly of the XZ-Unit

3.1: Mounting the X-Axis

3.2: Mounting the Z-Axis

3.3: Mounting the Timing Belt

3.4: Assembling the Extruder

4 Wiring

4.1: Wiring the Power Supply

4.2: Wiring the Z-Unit

4.3: Wiring the Y-Unit

4.4: Wiring the X-Axis

4.5: Gluing the Endstop Magnets

4.6: Uploading Firmware

4.7: Wiring the Extruder

4.8: Mounting the Heatbed

5 Calibration

5.1: Testing Functionality

5.2: Calibrating the Y Axis

5.3: Calibrating the X Axis

5.4: Calibrating the Print Platform

6 Printing

6.1: Filament Holder

6.2: Cura

6.3: Kisslicer

6.4: Dual Printing