-

Notifications

You must be signed in to change notification settings - Fork 20

Section 3.4 Assembling the Extruder

|

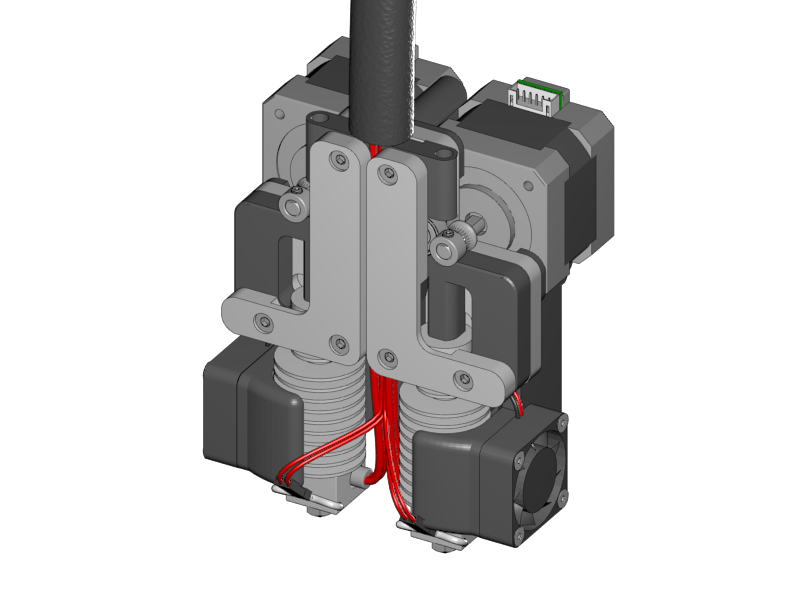

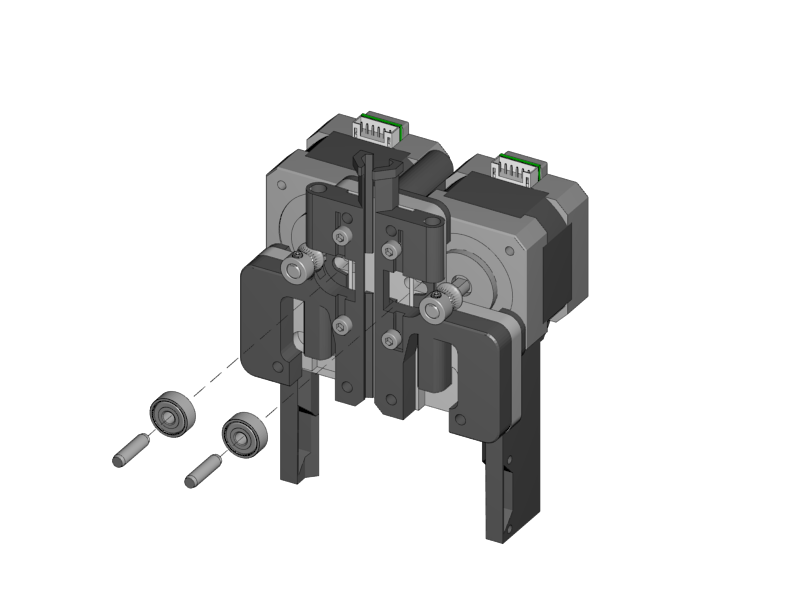

Finally it is time to build the extruder. The design of the extruder is made to be a dual extruder, but you can also make it a single extruder by leaving out the right hand motor and hotend.

|

|

|

|

|

-

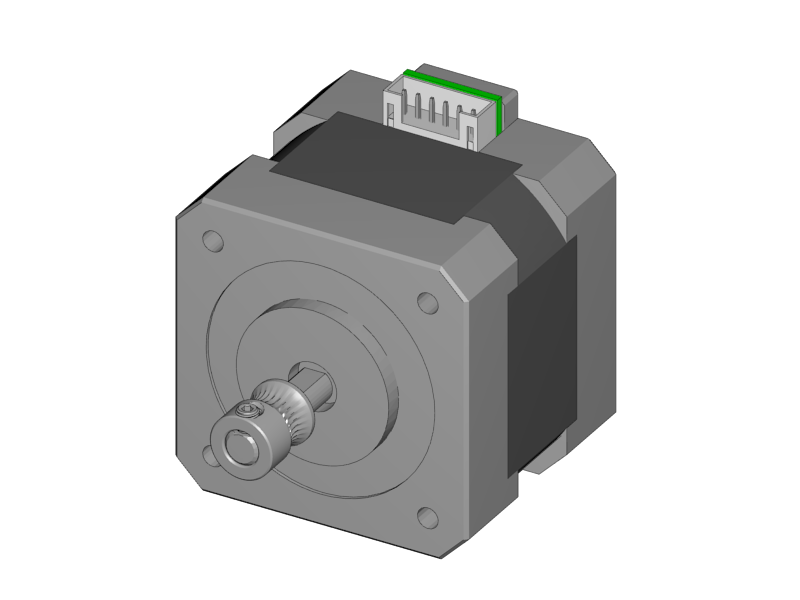

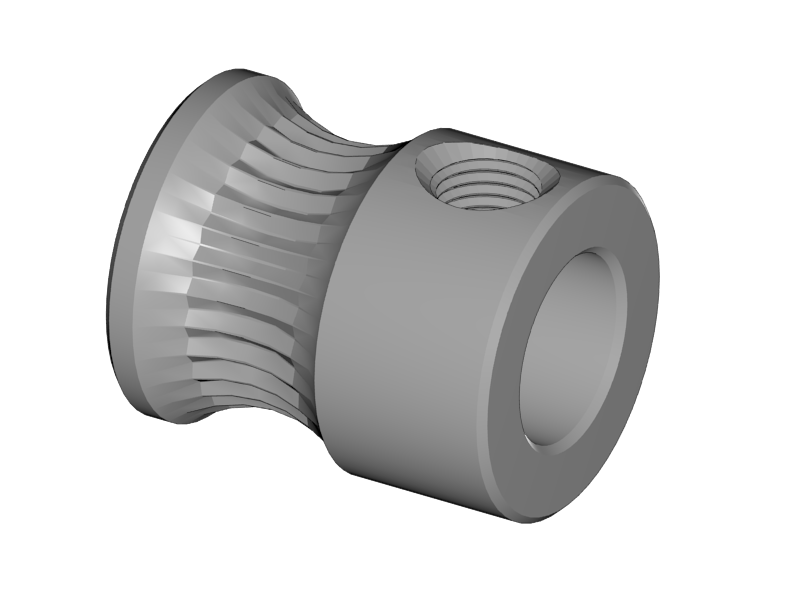

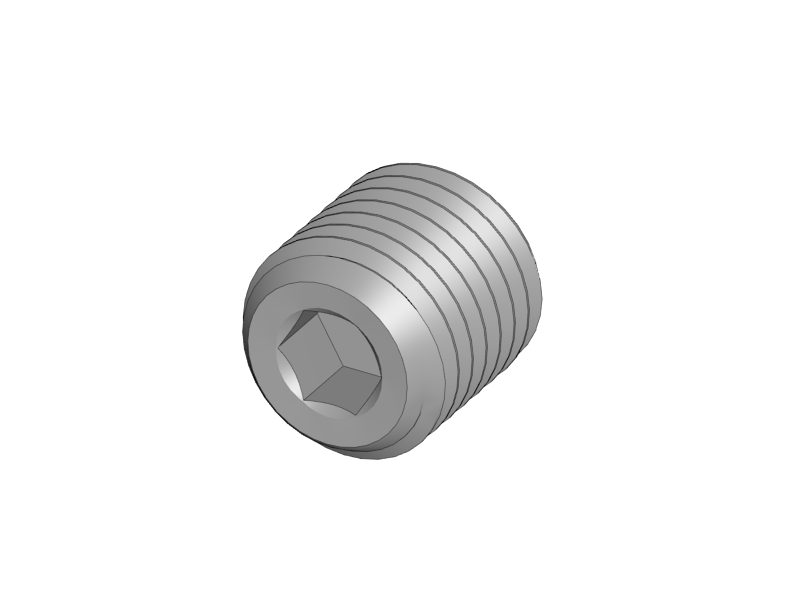

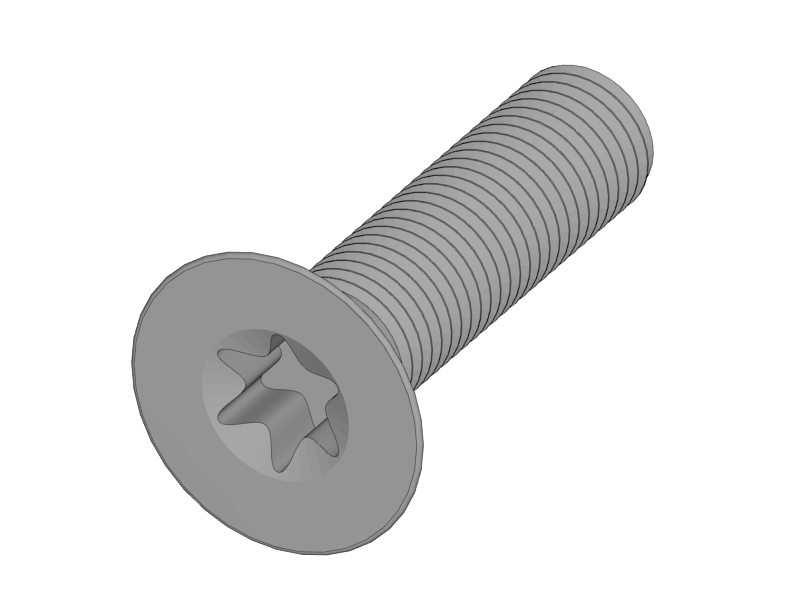

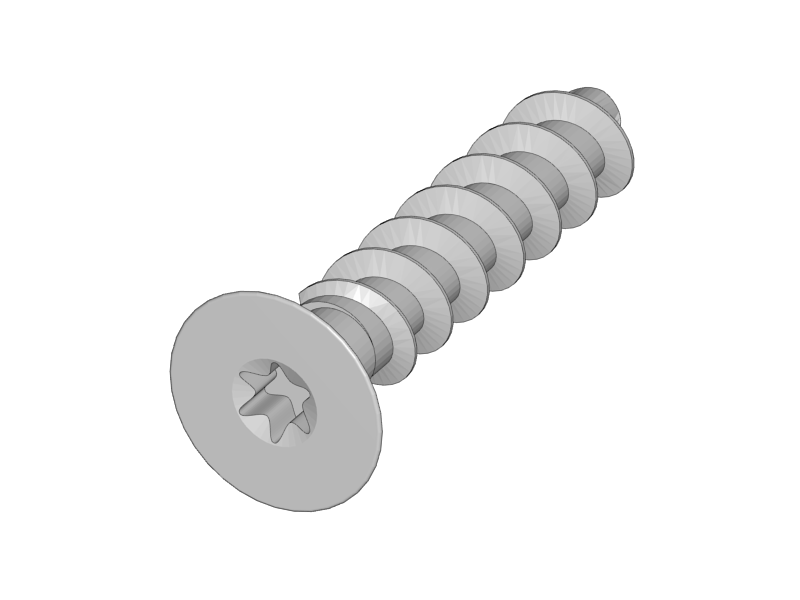

Turn the set screw into the filament pulley

-

Fix the filament pulley onto the motor shaft

-

Make sure that:

-

The screw is on the front

-

The screw touches the flat side of the motor shaft

-

!!! The front of the pulley and the motor shaft are not flush ( we got new motors with a longer shaft picture is not updated yet), once the extruder is assembled you can use a piece of filament to adjust the pulley to be in the right position. !!!

-

-

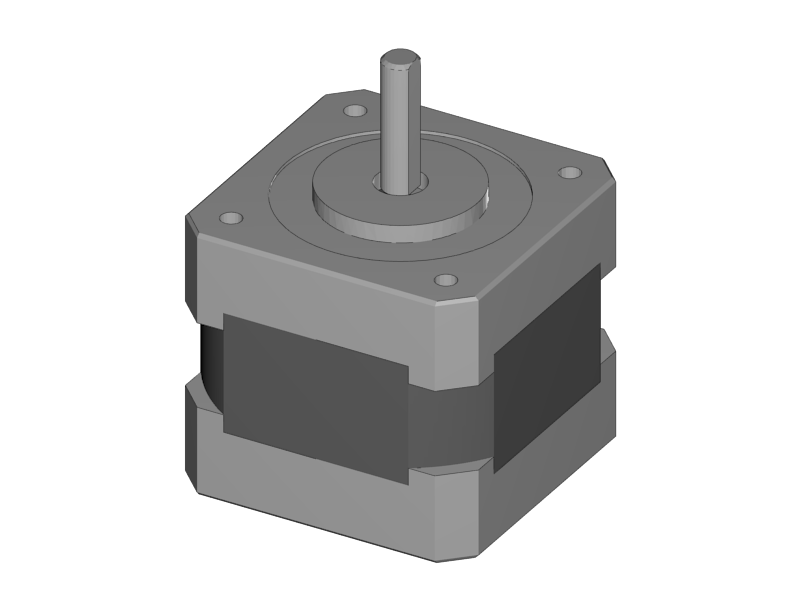

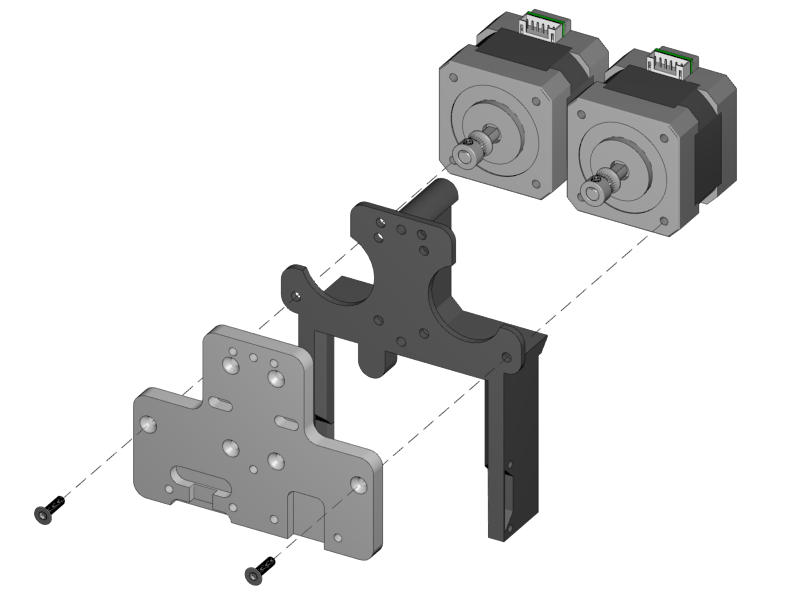

For a dual extruder, prepare two motors

|

|

|

|

|

-

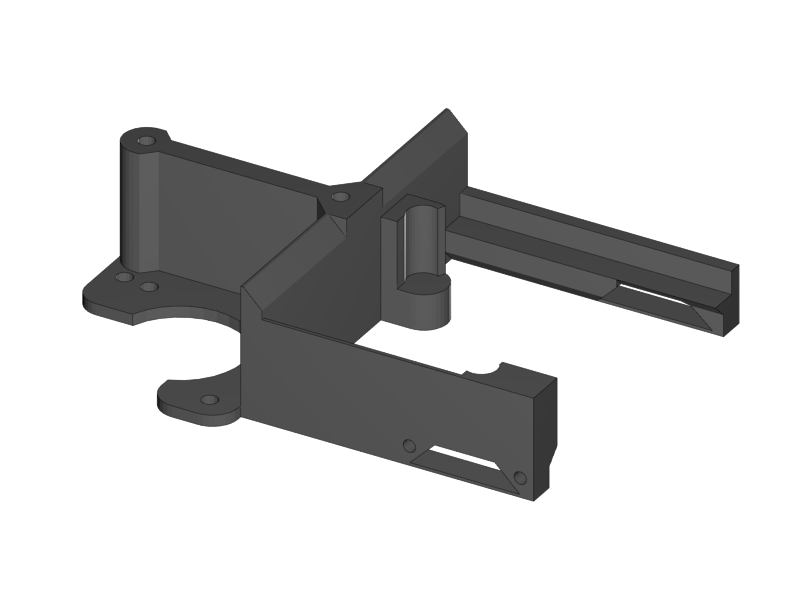

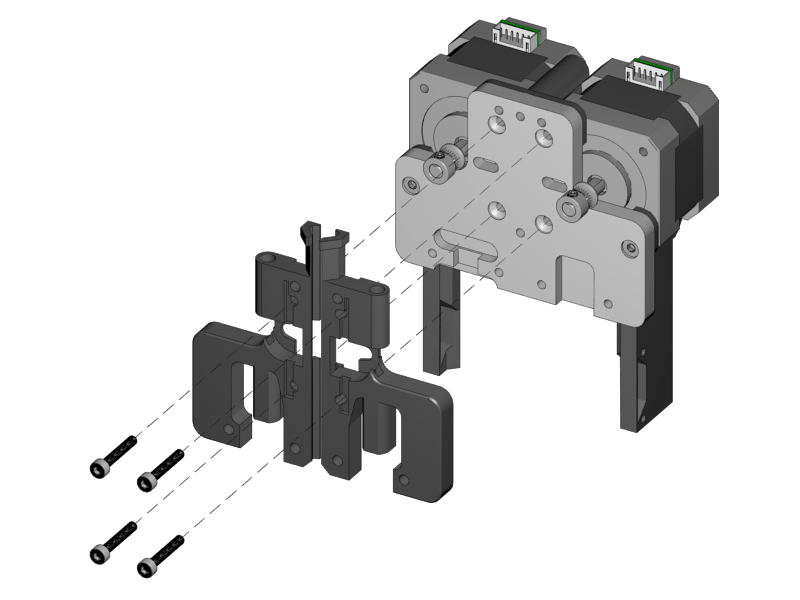

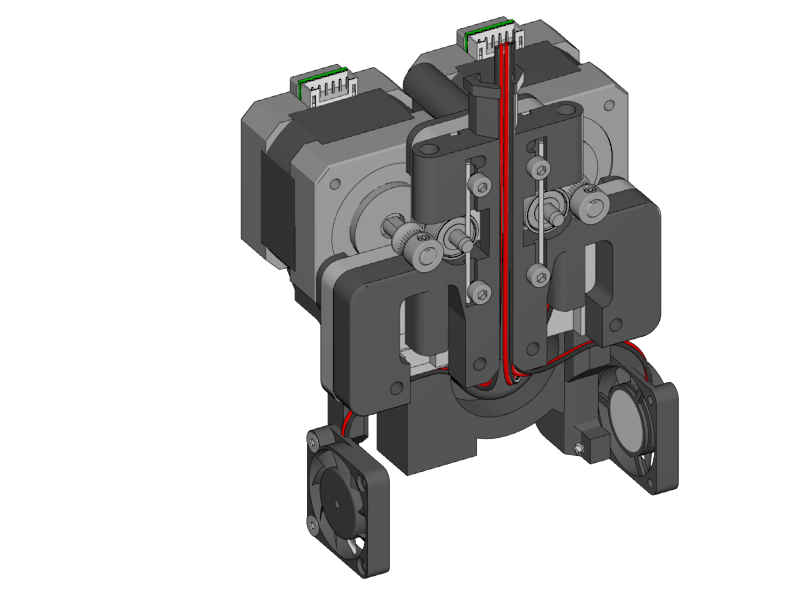

Mount both motors onto the fan holder and base plate

-

Make sure the motors are straight and tighten the screws well

|

|

|

|

|

-

Make sure the filament path is free. Test it with a piece of filament.

-

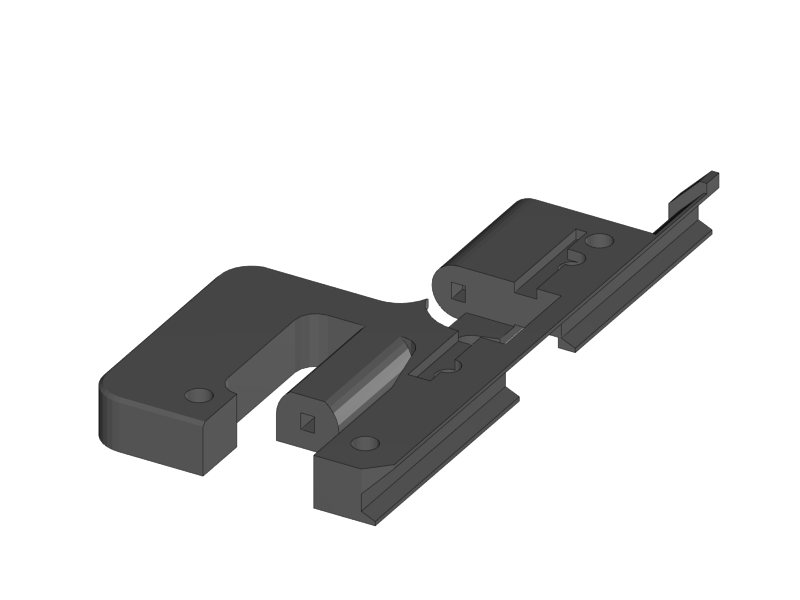

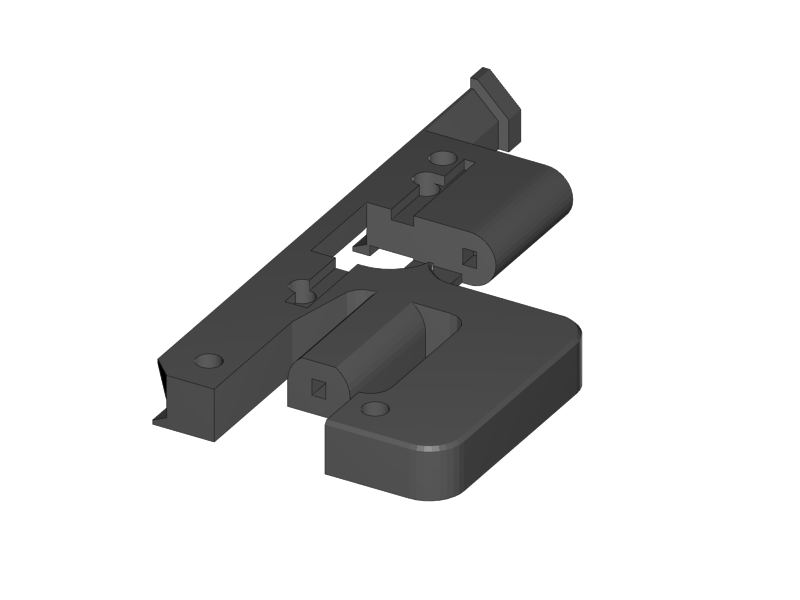

Put the plastic parts onto the assembly, but do not tighten the screws yet

-

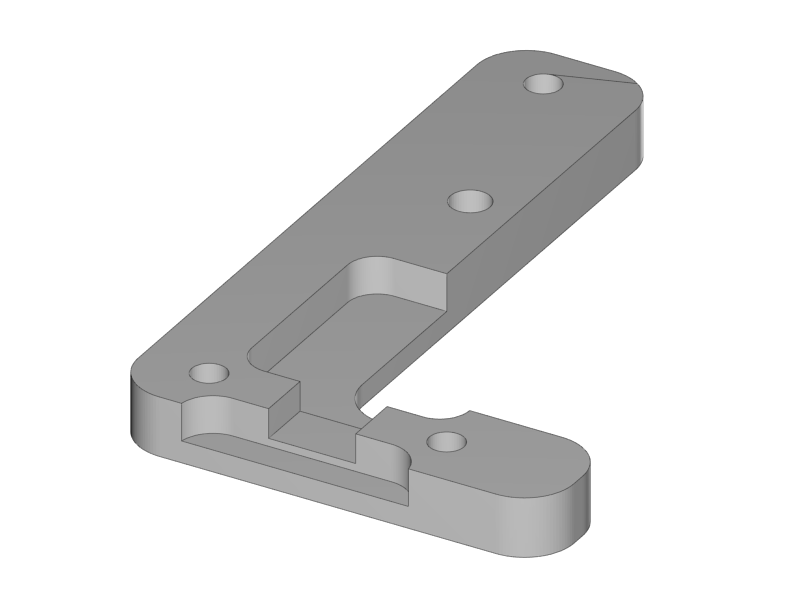

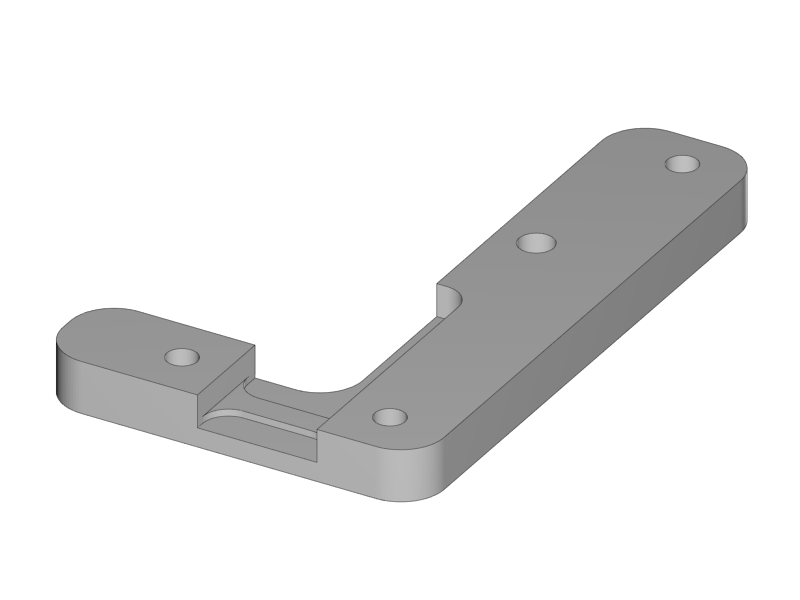

For single extruder put the right plastic part later, and fix it with the aluminium plate

|

|

-

Slide the extruder springs behind the plastic part.

-

Push them all the way in, with the aid of the other extruder springs.

|

|

|

-

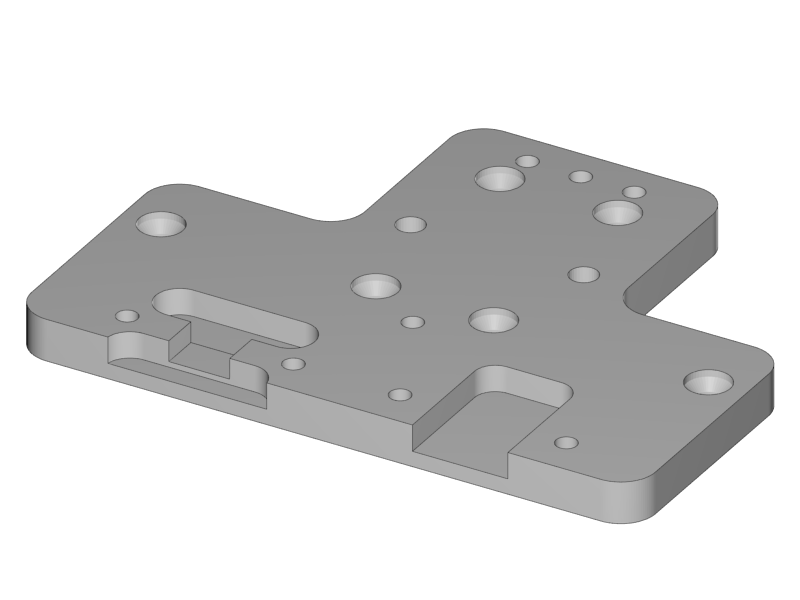

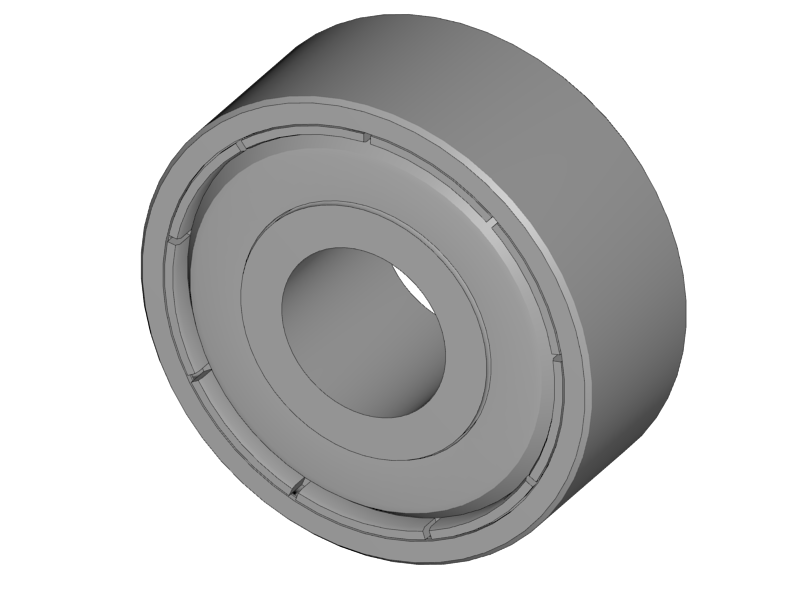

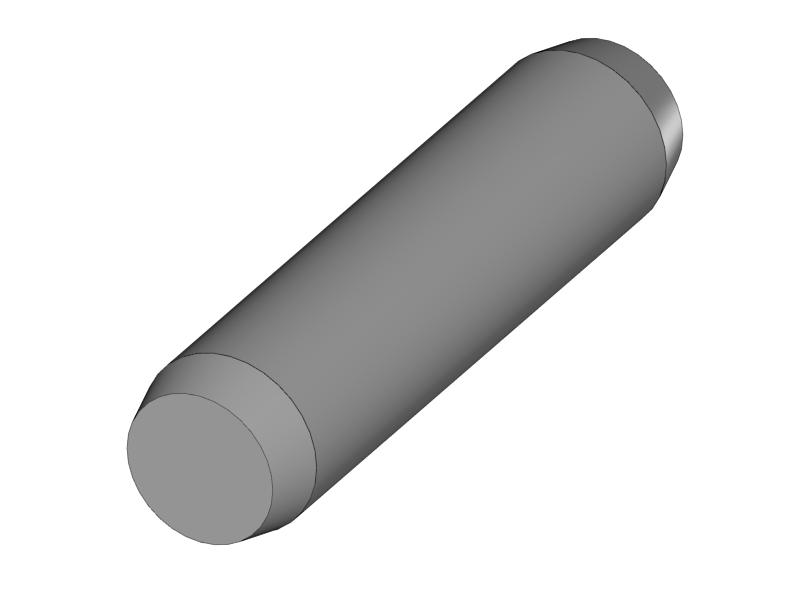

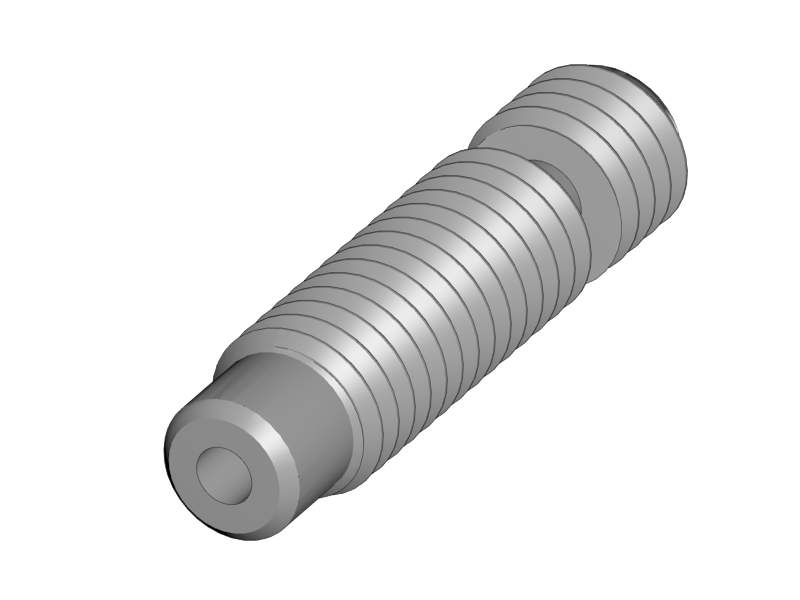

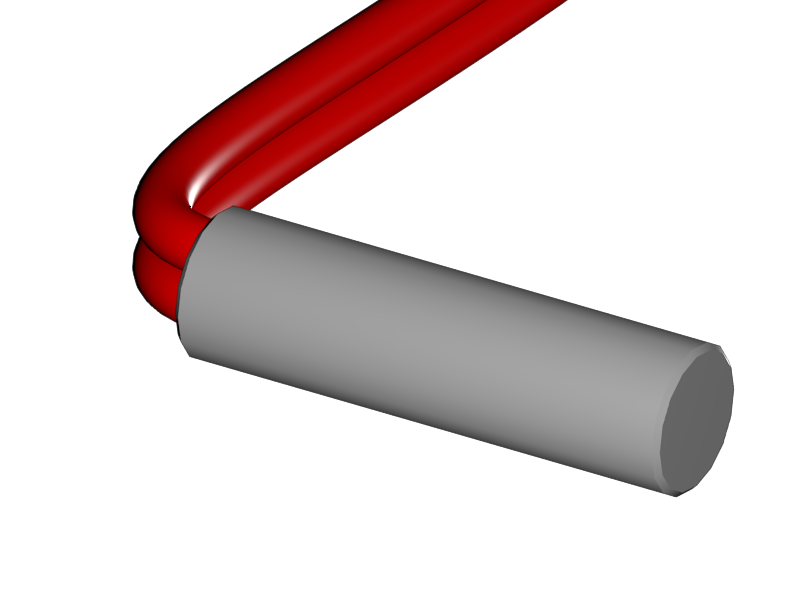

Put the dowel through the bearing

-

Place it into the slot hole of the aluminium base plate

-

Repeat for dual extruder

|

|

-

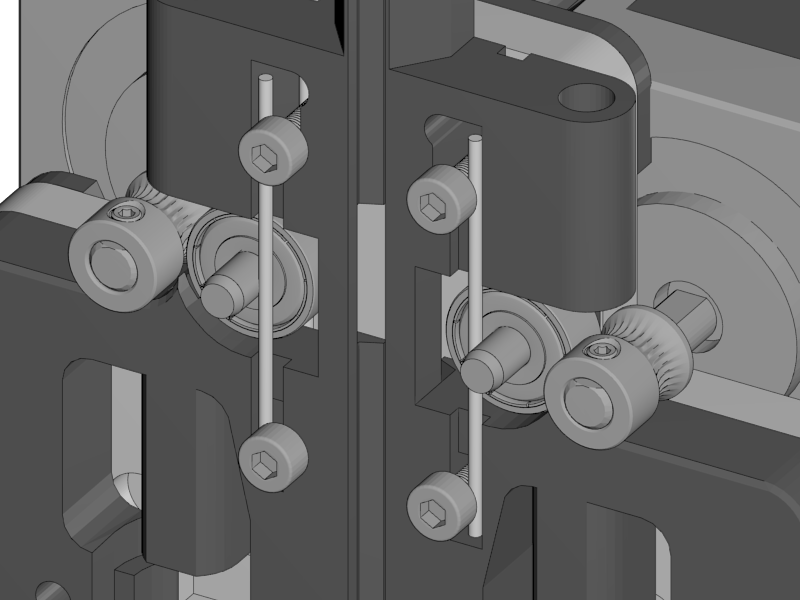

Slide the remaining two extruder springs behind the heads of the M3x20 screws

-

Tighten the screws (but not too tight!!)

-

The ball bearing is (almost) touching the filament pulley

-

|

|

|

|

|

-

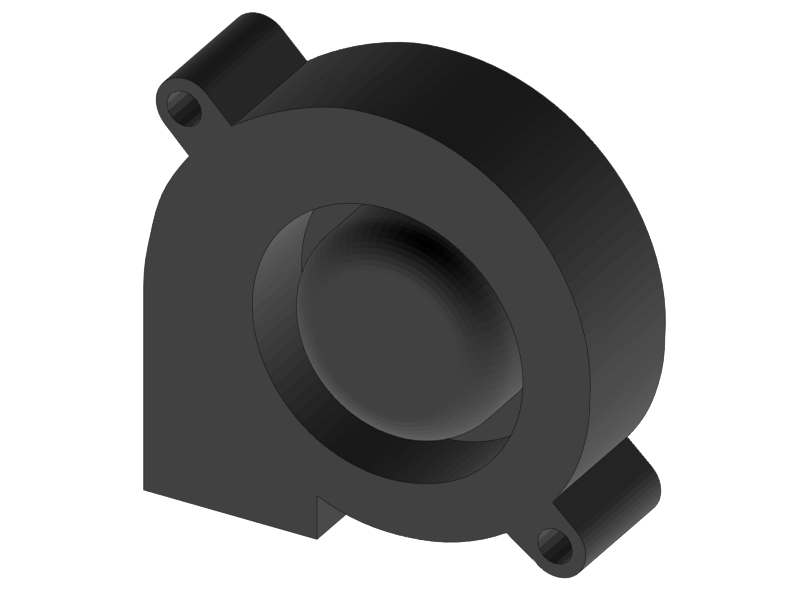

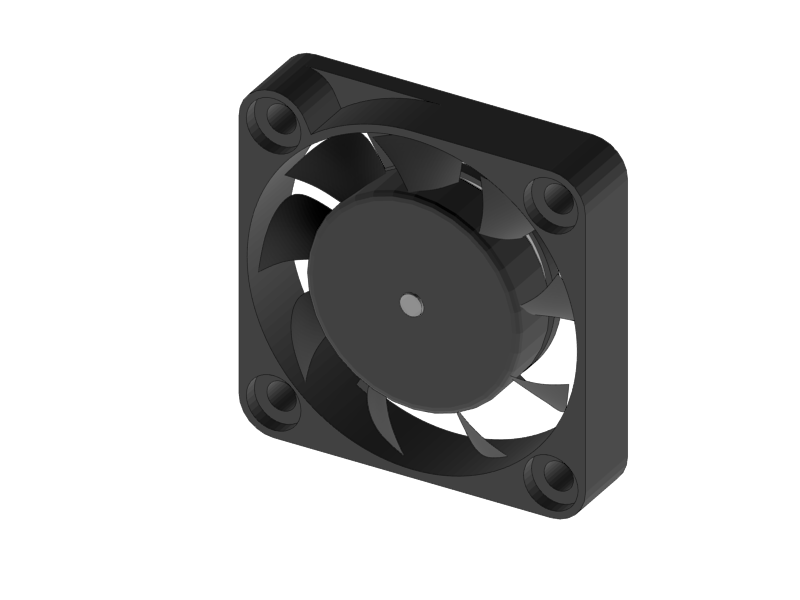

Click the radial fan into the designated slots of the extruder fanholder part

-

Lead the wire through the cable channel

-

-

Mount the fans onto the extruder fanholder

-

Make sure the wires for the fans are soldered so the fans are powered with 1 connector

-

Lead the cables through the cable channel

-

|

|

|

|

|

|

|

-

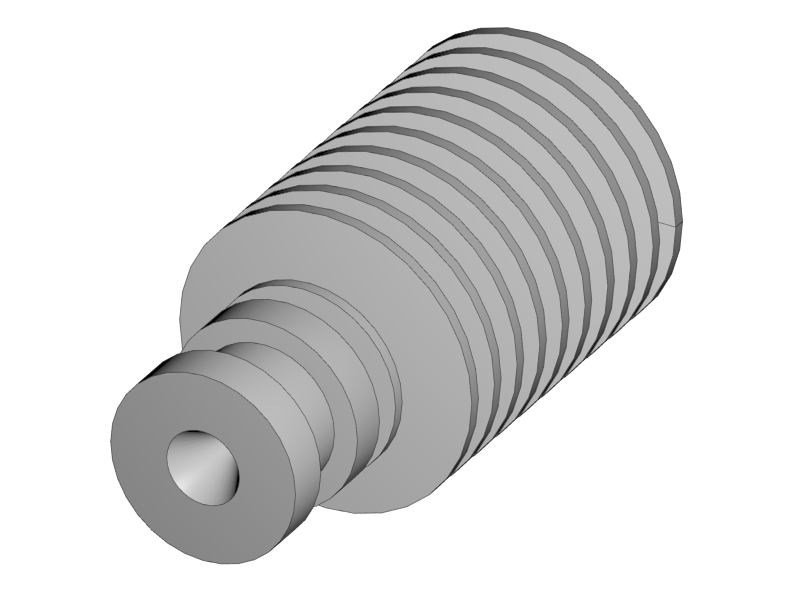

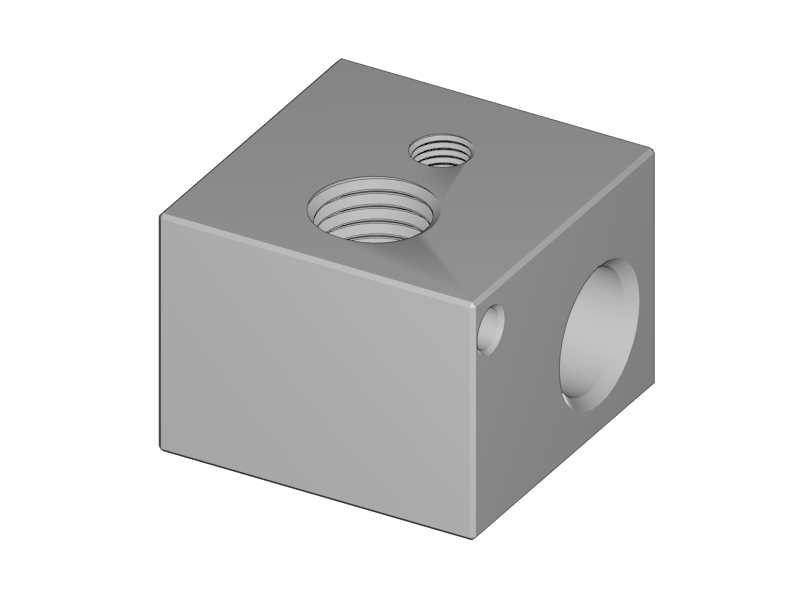

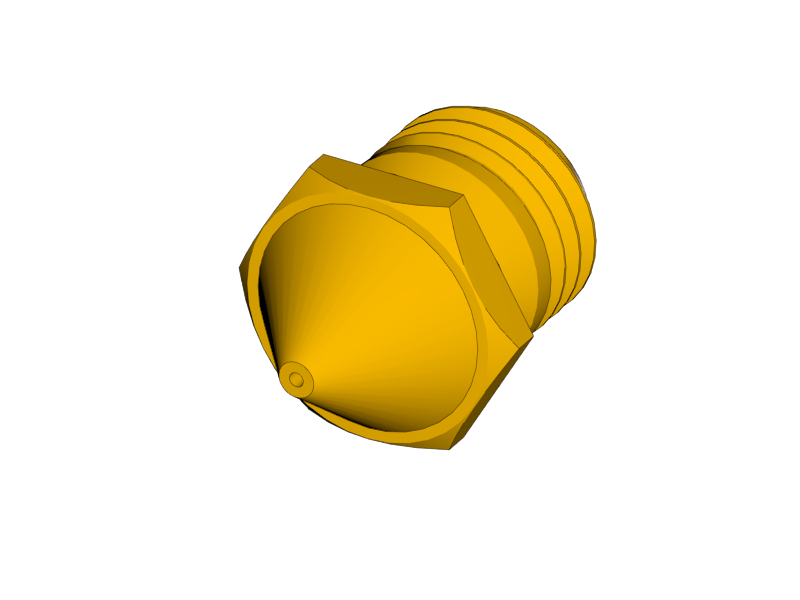

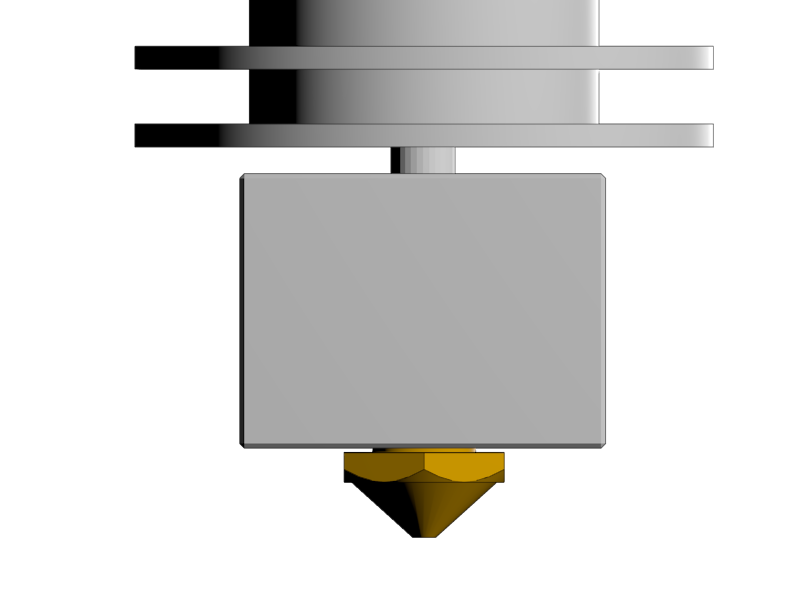

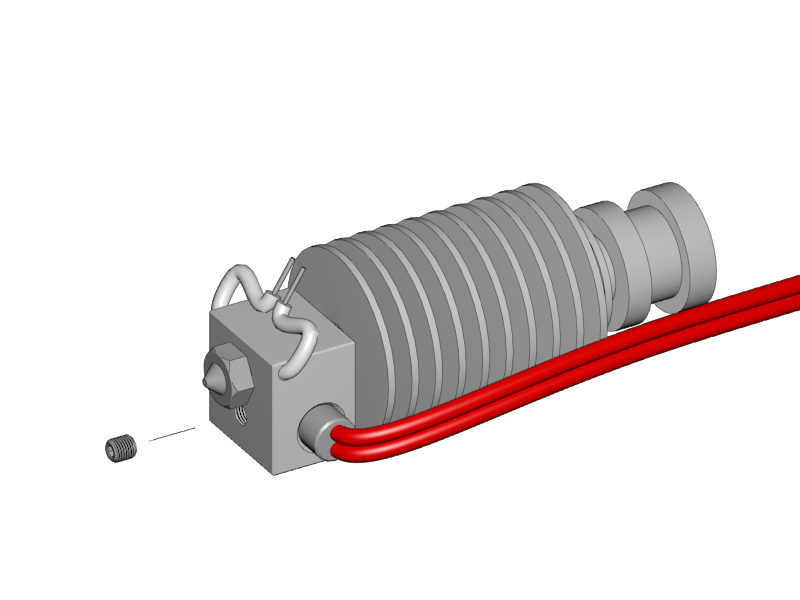

Screw the Heatbreak and the nozzle into the Heater Block

-

Handtight is well enough

-

there might be a teflon inliner , do not put it in yet

-

-

Screw the cooler body onto the Heatbreak

-

Make it tight, but only hand tight

-

Understand that the heatbreak has a very thin 'neck' which can be damaged with too high force

-

|

-

Adjust the nozzle in such a way that there is just a couple of tenths of a millimeter between the heater block and the head of the nozzle.

-

The neck of the heat break should be more or less flush with the top of the heater block

-

Everything is fixed, but only hand tight

-

Later the nozzle will be fixed while the hotend is heated to 300°C. This is to make sure the nozzle is press fit to the heat break

-

Fixing the nozzle like this also reduces mechanical load on the heat break while fixing the nozzle

-

|

|

-

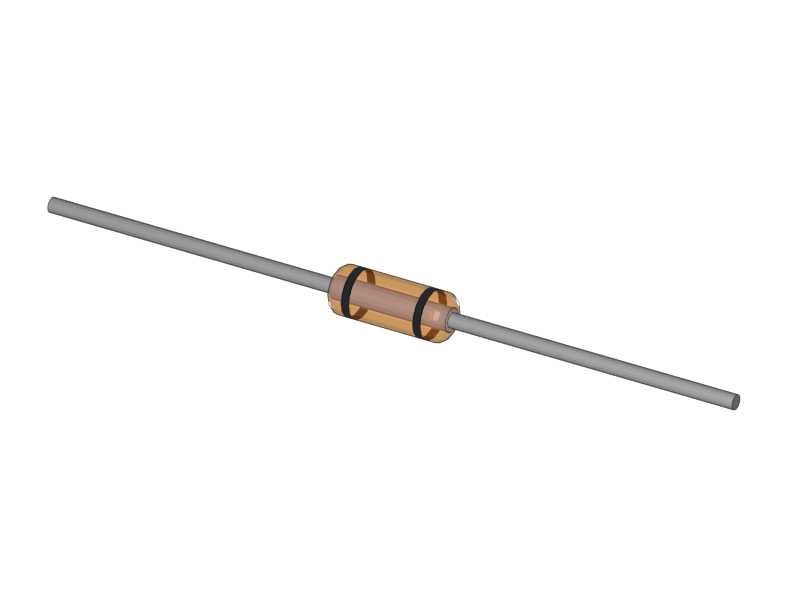

Put a piece of heat resistant insulation on both legs of the thermistor

-

Leave about 5mm of blank metal for connection

-

|

|

|

-

Slide the heat cartridge into the hole of the heater block

-

The left side of the cartridge should be flush with the heater block

-

Gently fix it with the set screw

-

In a dual set up the cartridges are mirrored. Use the picture of the next step as a reference

-

-

Slide the thermistor into the little hole

-

Make sure the thermistor is (more or less) in the middle

-

Bend the leads so it cannot slide

-

Bend the leads together so you can connect it later with a connector.

-

|

|

|

|

|

|

|

|

|

-

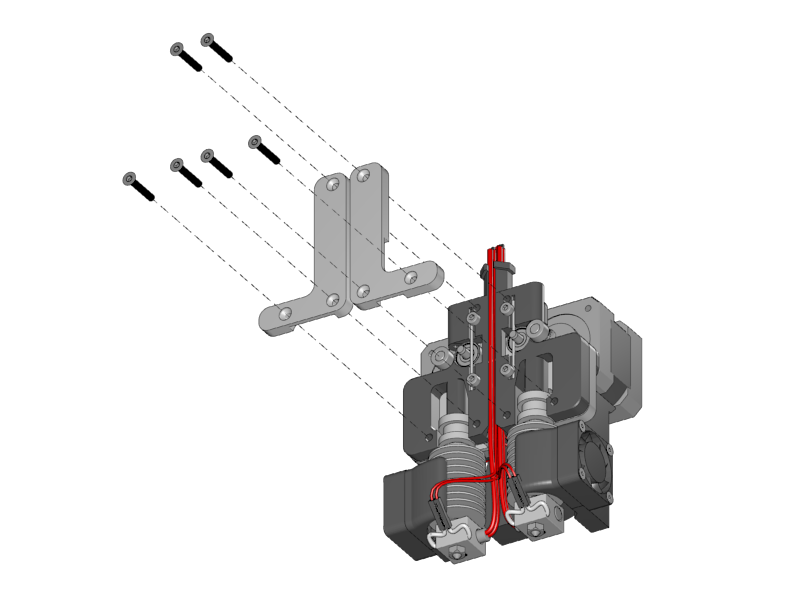

Put the hotends onto the extruder base plate

-

Connect the thermistors. Polarity is not important

-

Lead the wires through the wire channel

-

Lead the wires of the heat cartridges through the wire channel

-

Fix the hotends with the aluminium front-plates

-

The right hotend can slide some millimeters in it slot.

-

Mount it as far up as possible. The exact height will be adjusted later.

-

-

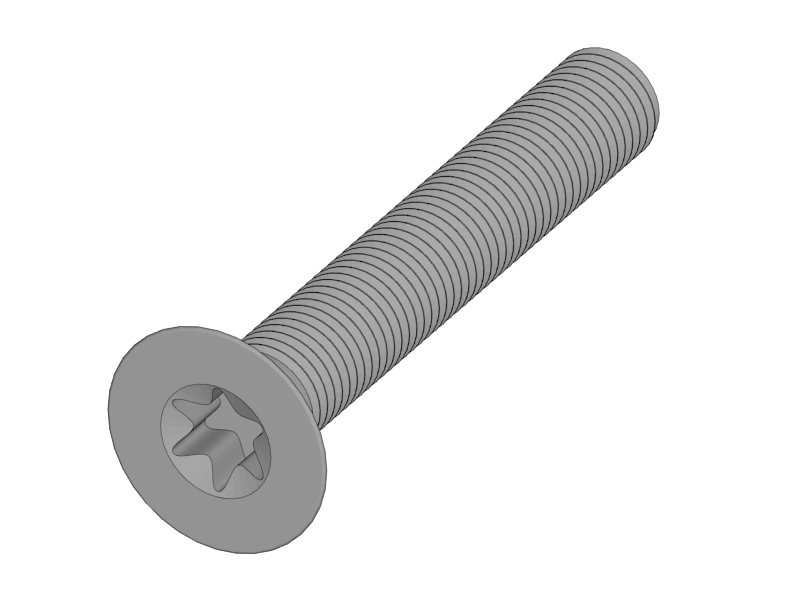

Mount the fan duct in front of the hotends with the torx screws

##i3 Berlin

1 Introduction

1.1: History

1.2: Tools and Parts

1.3: Preparing the Casings

2 Assembly of the Y-Unit

2.1: Rods and Power Supply

2.2: Front- and Back- Plate

2.3: Mounting Y-Carriage and Belt

3 Assembly of the XZ-Unit

3.1: Mounting the X-Axis

3.2: Mounting the Z-Axis

3.3: Mounting the Timing Belt

3.4: Assembling the Extruder

4 Wiring

4.1: Wiring the Power Supply

4.2: Wiring the Z-Unit

4.3: Wiring the Y-Unit

4.4: Wiring the X-Axis

4.5: Gluing the Endstop Magnets

4.6: Uploading Firmware

4.7: Wiring the Extruder

4.8: Mounting the Heatbed

5 Calibration

5.1: Testing Functionality

5.2: Calibrating the Y Axis

5.3: Calibrating the X Axis

5.4: Calibrating the Print Platform

6 Printing

6.1: Filament Holder

6.2: Cura

6.3: Kisslicer

6.4: Dual Printing